- Hot Stamping Door Impact Beam

- Laser Patch Work

- Clad Metal Busbar

- CFRP

- Mg alloy

- Hybrid Damping Steel Plate

-

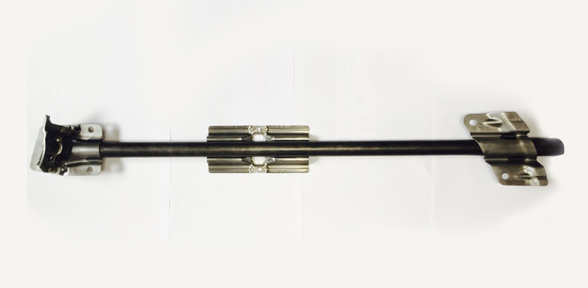

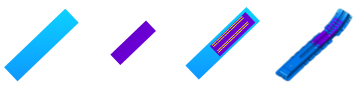

Hot Stamping Door Impact Beam

Hot Stamping Door Impact Beam Description H/S used integrated door impact beam development Before Development <Part Quantity: 5 Piece>

After Development <Part Quantity: 1 Piece>

Expected Effect Lightweight by 22% and cost reduction by 8% -

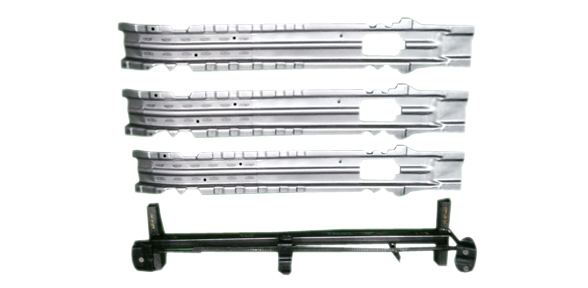

Laser Patch Work

Laser Patch Work Description Laser used patch work technology development Production Process MBR cutting/ REINF cutting/ Laser welding/ press forming

Expected Effect Productivity enhancement by 64% and cost reduction by 16% -

Clad Metal Busbar

Clad Metal Busbar Description Busbar development using clad (Cu+Al+Cu, 3 layers) instead of Cu

-

<Material Cross Section>

-

<Busbar>

Expected Effect Lightweight by 42% and cost reduction by 10% -

-

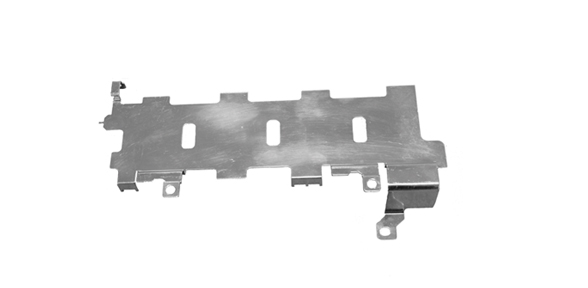

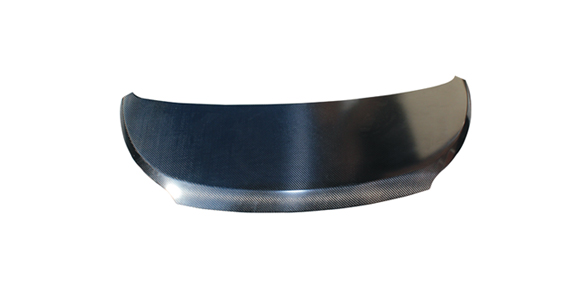

CFRP

CFRP Description CFRP material used car body part development

-

<HOOD>

-

<Door Impact Beam>

Processing Time 8 minutes (VA-RTM, Thermosetting epoxy resin) Expected Effect Lightweight by 46% (for hood) / 66% (for DIB) -

-

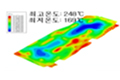

Mg alloy

Mg alloy Description Mg material used battery pack case development

-

<Battery Pack Case>

-

<Forming and Thermal Analysis>

Expected Effect Lightweight by 68% and excellent vibration absorption property -

-

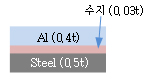

Hybrid Damping Steel Plate

Hybrid Damping Steel Plate Description Damping steel plate used dash development

-

<Material Cross Section>

-

<DASH>

Expected Effect Lightweight by 20% and excellent noise/vibration suppression property -